Non-contact quality control

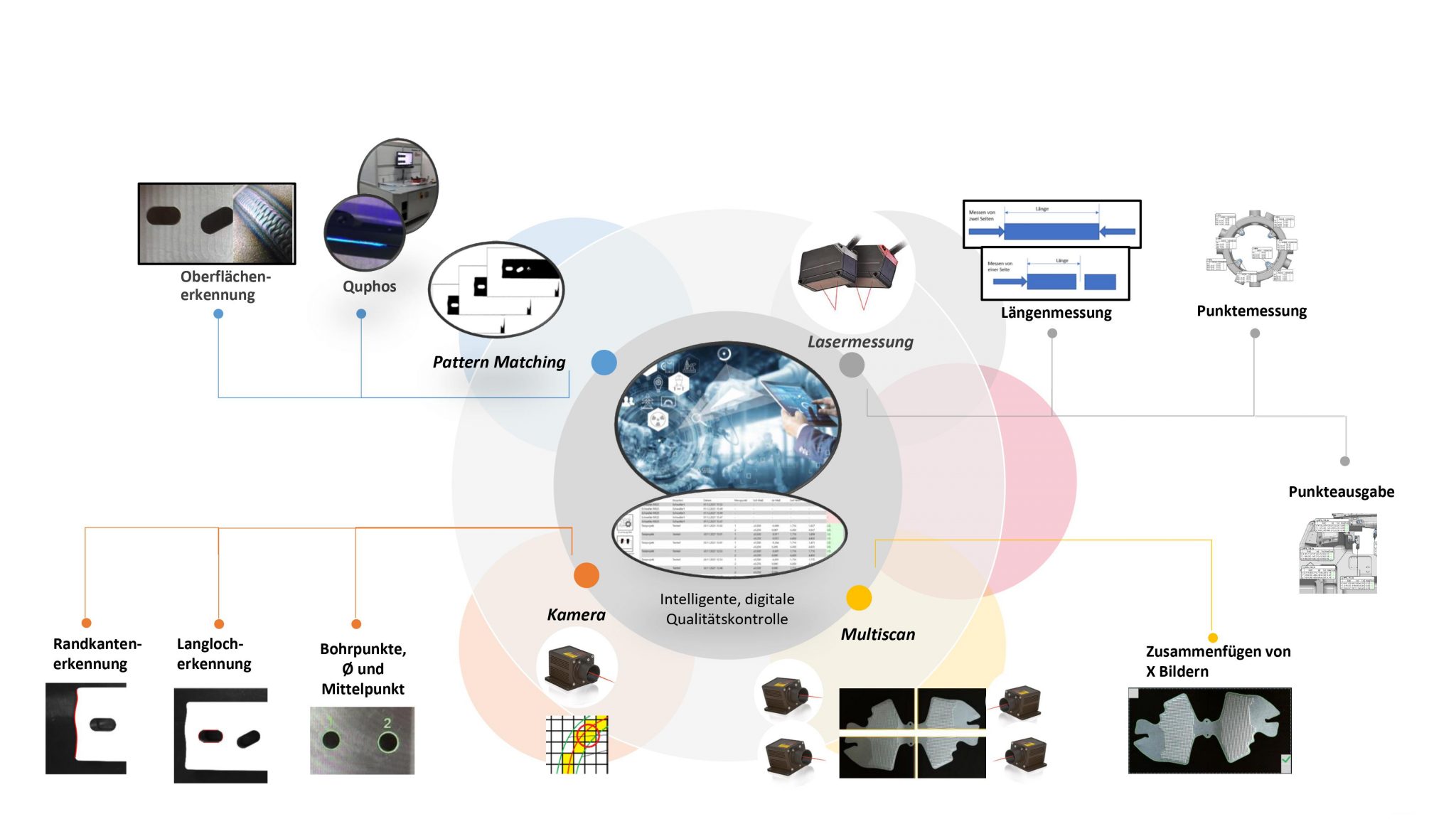

An intelligent combination of camera and laser technology in one software.

In order to continue to be considered an attractive partner in terms of quality assurance in the future, constant development and market observation are essential for companies. A pioneer in this area is the company Okulus, founded by David Bahr, with many years of experience in developing its own software. Oculus relies on the intelligent combination of camera and laser technology for component inspection and offers outstanding optical component measurement.

The photo-optical measurement from Okulus enables you to use a pioneering process that you will never find anywhere else. The measurement work is of the highest quality and ensures that the required standards in production are met. Numerous companies have already benefited from the precise tests and successfully implemented their project ideas.

With our expertise, you benefit from the best measurement work for your production. With photo-optical measurement, we offer you a pioneering process that you will not find anywhere else in this version. Optical component measurement is an essential step in production that you must always give the highest degree of recognition to, because ultimately it is about guaranteeing the required quality. Our measurement work has already helped numerous companies to successfully realize their ideas based on precise tests according to the desired requirements.

Photo-optical measurement not only enables the detection of surface defects, but also the detection and inspection of bores, slots, contours and measuring points. With this comprehensive procedure you can ensure that all relevant parameters of your components meet the desired requirements.

Whether it’s about checking the exact position of holes, measuring the length of elongated holes, analyzing the contours of components or recording specific measuring points – photo-optical measurement offers you a comprehensive solution for precise measurement work.

With optical component measurement you can ensure outstanding production

Rely on optical component measurement if it is important to you that perfection and precision are in harmony. Photo-optical measurement detects any deviation and is considered the best way to carry out measurement work quickly. If you don’t want production to stall, photo-optical measurement is the best choice. We offer you numerous options for optical building surveying that also suit your individual requirements. Don’t let any time go by, because as we all know, this is money and shouldn’t affect your profitability. Instead, trust our experienced engineers to assist you with measurement work that leads to accurate determinations.

Why automate the testing process?

100% Qualität

Fehlerhafte Teile und Überschreiten von Toleranzen, werden zuverlässig und auto-matisiert erkannt.

Spürbar weniger Personaleinsatz

Vollständige automatisierte

Prüfprozesse, reduzieren

nachhaltig Kosten

durch weniger Personal.

Kürzere Taktzeiten

Schnellere Prüfprozesse, reduzieren die Taktzeit und schaffen höhere Fertigungseffizienz.

Mehr Prozesssicherheit

Trendbestimmungen und das automatische Erkennen von Zusammenhängen, schaffen sichere Prozesse.

Vollständige Rückverfolgbarkeit

Prüf-, Mess- und Prozessparameter, werden vollständig und lückenlos dokumentiert.

100% quality

Defective parts and exceeding tolerances are detected reliably and automatically.

Noticeably less personnel deployment

Completely automated

testing processes, reduce

sustainable costs

through fewer personnel.

Shorter cycle times

Faster inspection processes, reduced cycle times and greater production efficiency.

More Process reliability

Trend determinations and the automatic recognition of correlations create reliable processes.

Complete traceability

Test, measurement and process parameters are fully and completely documented.

100% quality

Defective parts and exceeding tolerances are detected reliably and automatically.

Noticeably less personnel deployment

Completely automated

testing processes, reduce

sustainable costs

through fewer personnel

Shorter cycle times

Faster inspection processes, reduced cycle times and greater production efficiency.

More process reliability

Trend determinations and the automatic recognition of correlations create reliable processes.

Complete traceability

Test, measurement and process parameters are fully and completely documented.

For this reason, photo-optical measurement is the best choice for your project

Equipped with the best software solutions, photo-optical measurement is ready for you. Camera lenses capture the components precisely and scan them precisely. This means that defects on the surface of materials, such as deformations or breaks, are immediately detected. Your advantage here is the prevention of errors that have crept into the production process but were often barely detected or detected too late. So that you can build on a process right from the start that supports the production process, photo-optical measurement is a successful solution that many companies use to protect themselves. Often even the smallest deviation can be a problem for successful continuity. To ensure that these do not appear in the first place, you should only have the optical component measurement carried out by professionals. Our employees are trained experts in the field and will be happy to demonstrate to you the advantages of such an analysis using photo-optical measurement. Use measurement work that leads to excellent results and detect errors before it is too late. In many implementations, deviations can not only be annoying, but also become dangerous. To prevent this, measurement work must be started early and be as precise as possible.

Use photo-optical measurement for particularly precise results

We have been using photo-optical measurement reliably and precisely for years when it comes to optical component measurement. Our measurement work covers a wide range of solutions and is used for both small and large objects. Our measuring room is equipped with the latest technical specifications with the most modern and innovative analysis methods for optical component measurement. Photo-optical measurement can even detect inaccuracies of up to 0.02 mm, which the human eye can hardly notice. The scan tells you everything you need to know about the surface condition and immediately detects deviations. Our scan data sheet at the end of the measurement work provides a suitable basis for further processing.

We are the first point of contact for your measurement work

Are you looking for a partner for solutions in all kinds of measurement work who impresses with their experience in the areas of component measurement? Then we are at your side and use optical component measurement to help you detect deviations in work items and other objects at an early stage. If components have to interlock, deviations may only have a small tolerance, otherwise the function will be prevented. The photo-optical measurement enables the testing to be carried out using the latest technology. Optical component measurement offers you the best support for a variety of manufacturing processes. You can also use our optical component measurement, for example, when measuring work on tools or model components needs to be done. The size of your components does not initially matter to us, because we carry out individual measurement work for each client that fits the respective requirements and only achieves the desired results in the end through this optical component measurement. Our team of engineers will explain the available options to you in detail and thereby offer you a high level of reliability through photo-optical measurement, which you have not yet been able to experience in this version.

Find out now about further, individual measurement work

Optical component measurement offers a wide range of possibilities as a basis for measurement work. With photo-optical measurement, you end up with results that are significantly more precise than was the case with conventional component measurements just a few years ago. Using optical component measurement, the focus is specifically on technology and scanning processes that scan surfaces precisely and thus detect errors more quickly. It’s best to use our optical component measurement today and benefit from measurement work that suits your requirements. Professional, modern and reliable, we offer you quick results at fair conditions and precise measurement work. Contact us today and talk to our engineers about how to proceed.