Test gauges

Gauge construction - test gauges - attributive gauges - gauges automotive industry

Attributive lessons

front apron

Attributive theory and vehicle interior

Attributive

prototype theory

Building gauges for more structure in commissioned work

In the automotive industry, gauge construction plays a crucial role in ensuring that various features such as the simulation of the vehicle environment and the control of the installation situation on the vehicle can be checked precisely. It is very important that holes are of the appropriate depth, angles correspond to the desired orientations and gaps are maintained correctly. In order to implement these guidelines efficiently, an analysis based on specific lessons from gauge construction is essential. We are an established partner in this area and have specialized in gauge construction for years in order to implement orders more efficiently and with the highest quality. Our tailor-made solutions in gauge construction make it possible to test vehicle components quickly and reliably, which saves time and costs and at the same time strengthens our customers’ innovative strength.

These functions are implemented in gauge construction: perfect for checking the target condition

Our company is an experienced and successful partner in gauge construction that has been implementing individual project ideas for many years. Our specialist designers produce bespoke test gauges tailored to the specific requirements of each job. By using lessons from our gauge construction, companies can save time and money while relying on the highest quality and innovation.

Various functions are implemented in gauge construction that enable quick and precise testing of the target condition. Tolerance ranges can be defined that differ from order to order. The designs developed in gauge construction are not used to record measurement results in numerical form, but rather enable direct and uncomplicated testing.

Various implementations in gauge construction for various types of orders

Gauge construction is used in various areas and depends on the individual specifications of the order. In this way, testing devices can be implemented to ensure quality in operational processes, to test surfaces, heights, angles or axes, as well as setting gauges in gauge construction.

For this reason we are number one in gauge construction for you

Stability plays a crucial role in gauge construction, as the manufactured gauges have to withstand high pressure and fluctuating temperatures. That’s why we use high-quality materials such as aluminum or plastic when making gauges and adapt the implementation individually to the requirements of the project.

As a leading partner in gauge construction, we stand for competence, precision and customer satisfaction. Our tailor-made solutions in gauge construction help companies to simplify their production processes and achieve high-quality results. If you are looking for a reliable partner for gauge construction, do not hesitate and contact us today. We would be happy to show you how gauge construction can advance your company.

Efficient test gauges for the automotive industry - precise results with maximum stability

Unsere Prüflehren zeichnen sich durch exakte Ergebnisse und eine hohe Stabilität, selbst in schwierigen situationen, aus. Als erfahrener Anbieter im Lehrenbau bieten wir erstklassige Prüflehren, die den individuellen Anforderungen unserer Kunden gerecht werden. Mit unserem hohen Fachwissen und langjähriger Erfahrung im Bau von Prüflehren sind wir ein verlässlicher Partner für Unternehmen in der Automobilindustrie.

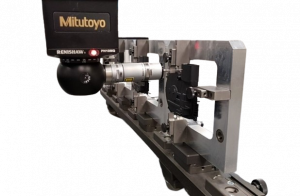

Test gauges for checking: Our test gauges have these properties

Through state-of-the-art construction methods and the use of 3D processes, we create complex test gauge components that can also cope with demanding tasks. We rely on high-quality materials such as aluminum, steel or plastic to produce test gauges for every area of application.

Score points with our test gauges in quality assurance at all levels

Our testing gauges are used in a wide variety of business sectors where precise testing of objects is necessary. With the test gauges made by experts, operational processes can be checked quickly and reliably. Our test gauges are characterized by precision, repeatability and comparative precision, linearity and high stability.

React quickly to changes in processes with test gauges: That’s why our test gauges are the best choice

Thanks to our testing gauges, companies can optimize their quality assurance at all levels. The test gauges enable quick and easy tests, measure tolerance ranges and help save time. The flexibility of our test gauges allows companies to react quickly to changes in processes and have the test gauges adapted accordingly.

Ideally, contact us today for high-quality test gauges

Our team of experts will be happy to provide you with advice on the subject of testing gauges. Use our high-quality testing gauges and optimize your processes. Contact us today and let our test gauges convince you. We look forward to your call!

Your reliable partner for high-quality attributive theory in the automotive industry

Are you looking for precise attributive theory and a company that precisely implements your requirements using state-of-the-art technology? Then we are the best choice for long-term, convincing attributive theory. We offer first-class quality and high stability, which have already enriched numerous companies in various industries.

What are attributive doctrines? – Definition and meaning

Attributive doctrines are always used when a predefined measure or a specific form is to be represented. They play a crucial role in checking TARGET and ACTUAL states to determine whether an object meets the specified requirements. Attributive teachings do not produce numerical results, but test in a function-oriented manner and provide visual results. Our attributive gauges comply with common standards, but also offer flexibility in design to meet individual requirements.

Individual implementations of attributive teachings

Each assignment requires customized attributive tenets that enable specific analyses. As a communicative team of experts, we are your partner for creating individual attributive teachings that are tailored precisely to your requirements. With our many years of expertise and experience in the production of attributive gauges, we have already convinced many industries.

Quick testing with attributive teachings of the highest quality

Our attributive gauges enable quick and precise testing of all types of processes. Thanks to modern manufacturing processes, including 3D technology, our attributive gauges ensure high accuracy and optimal results. With us you receive attributive teachings that can be flexibly adapted and work efficiently even when changes and adjustments are made.

Rely on our high-quality attributive gauges and benefit from long-term quality and precision. Contact us today to discuss your attributive teaching needs. We look forward to working with you.

Lessons learned in the automotive industry: Trust in precise quality assurance

When it comes to gauges in the automotive industry, accuracy is paramount. As an experienced company with well-known customers from various industries, we successfully offer gauges for the automotive industry that simplify measurement and testing and make production processes more efficient. Our lessons for the automotive industry are impactful on a broad level and are becoming increasingly important, as many components are individually manufactured in small quantities or have yet to prove themselves on the market.

Reliable partner for teaching in the automotive industry

No matter whether for general tests or specific measurements, our teachings in the automotive industry already support many companies. From cars to commercial vehicles to special models – our lessons in the automotive industry are used in various work environments. Thanks to the latest technology, we offer gauges in the automotive industry that work more precisely than ever before and can easily test even unusual objects.

Teaching in the automotive industry for diverse requirements

Teaching in the automotive industry for diverse requirements

Our teachings in the automotive industry are convincing in a variety of areas of application. From bus design to truck spare parts, our lessons in the automotive industry impress with precision and quality. No matter whether cars, trucks, commercial vehicles or motorcycles – our teachings in the automotive industry meet the highest standards and are flexibly adaptable.

Individual properties and tolerance ranges

Our automotive gauges offer individual tolerance ranges and can be tailored specifically to the requirements of each job. As a testing system, our teachings in the automotive industry serve to accelerate production processes and offer a reliable solution. From door panels to center consoles, our teachings have a wide range of uses in the automotive industry.

Rely on accurate gauges in the automotive industry

Our lessons in the automotive industry focus on quality and precision. Contact us for an individual offer and benefit from our specialist knowledge and many years of experience in the field of gauges for the automotive industry. Trust in the best quality assurance support and optimize your production processes with our lessons in the automotive industry. We look forward to your inquiry!

Our experience in attributive gauges, test gauges, gauge construction and in the automotive industry

Due to the increasing importance of quality control over the decades, especially in the automotive sector, we took our first steps in the field of producing manual attributive gauges 20 years ago. We have been able to develop a very good reputation in this area over the years and have gained regular customers. Today we deliver our teachings worldwide.

With our manufacturing capabilities and expertise, we can supply testing gauges for small plastic components through to testing gauges for rear and front spoilers. We also produce your setting gauge for formed sheet metal parts (e.g. shielding plates, motor mounts, etc.) as well as measuring fixtures for repeatable measurements on the measuring machine.

However, Bahr GmbH & Co. KG is not only a manufacturer of manual attributive gauges. Rather, we look at the holistic process of quality control, specified by the requirements for the product (individual parts or assemblies).

Quality control as a holistic process

We are aware that the recording concept of the measuring system and the recording of the coordinate measuring machine must be coordinated with one another in order to achieve a meaningful correlation. For this reason, it is important to us to be able to provide you with a harmonious overall concept. Ultimately, the high quality of your products should be guaranteed with our help.

Quality control: A guarantee of success for long-term partnerships

In today’s competitive landscape, it is crucial for companies to stand out through continuous quality improvement and remain attractive partners in terms of quality assurance in the long term. One company that is successfully following this path is the company Okulus, founded by David Bahr.

David Bahr and his team at Okulus have developed outstanding expertise in quality control over many years, focusing on constant development and market observation. This strategy has made Okulus a reliable and sought-after partner when it comes to quality assurance.

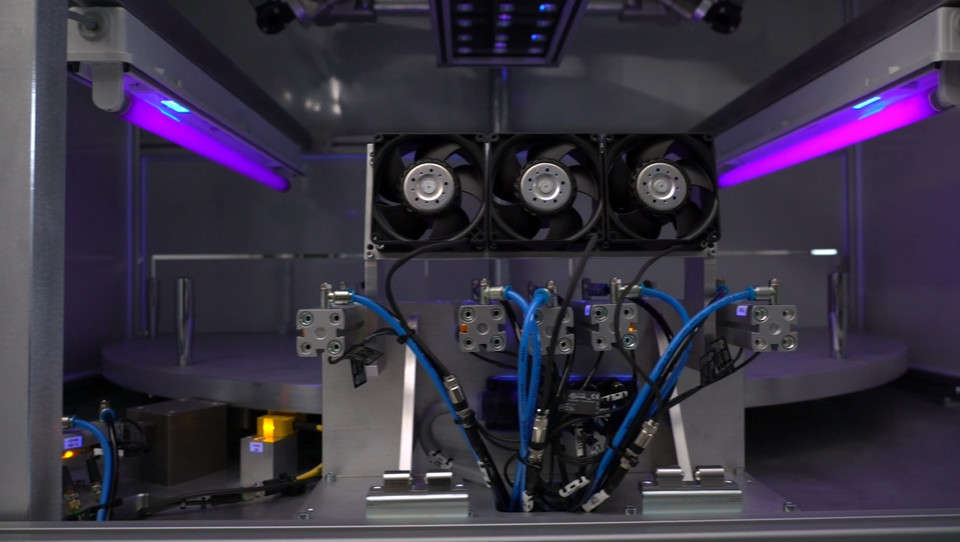

A key factor in Okulus’ success is the long-term development and optimization of its own software solutions. These tailored tools enable the company to overcome specific quality control requirements and challenges and achieve unmatched precision.

A special innovation from Okulus is the intelligent combination of camera and laser technology for component inspection. By using the latest technologies and algorithms, Okulus can detect errors and defects at an early stage, which not only reduces the reject rate but also increases overall efficiency.

The high precision and efficiency of Okulus quality control systems are a result of the passion for innovation and the tireless search for excellence. The company continually stays ahead of the curve to ensure that its solutions are in line with the latest technological developments.

As a quality assurance partner, Okulus is able to offer tailor-made solutions for various industries. Whether in the automotive, aerospace, electronics or manufacturing industries, Okulus’ quality control creates trust among customers and partners alike.

In summary, Okulus is a pioneer in quality control thanks to the vision of David Bahr and his team. The combination of constant development, the use of our own software solutions and the latest technologies has made Okulus a trustworthy partner who remains an attractive contact for quality assurance even after many years.Start of form

Because this method offers so many possibilities, we have dedicated a separate section to it on our homepage. Feel free to take a look at the “Automated Quality Inspection” tab and learn more about the possibilities of this exciting field or contact us and describe your problem. We will be happy to find the optimal solution.